Here at K&L Clutch & Transmission, we make it our business to supply you with the highest-quality torque converters for industrial machinery, including:

- Allison torque converters

- Twin Disc torque converters

- Manitowoc Torque Converters

- Clark torque converters

But it’s also our mission to supply information and understanding about our products to better help you choose which hydraulic torque converters best fit your needs.

So let’s take a look some key hydraulic torque converter facts you should know.

hydraulic torque converter facts

1. Hydraulic torque converters are pretty simple

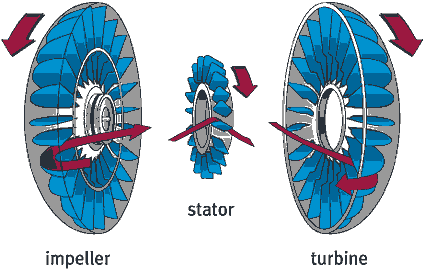

A hydraulic torque converter can be broken down into three main components:

- Impeller

- Stator

- Turbine

The impeller, or pump, is a ring of metal blades driven by the engine shaft that transfers kinetic energy by flinging fluid around. Its spinning motion also draws more fluid into the center by creating a vacuum.

The fluid from the impeller eventually hits the turbine “” a set of three-ring blades connected to the engine shaft. The pressure from the fluid turns the turbine, which causes the transmission to spin, thus powering the machine.

The fluid then exits the turbine in the opposite direction, away from the engine and pump spin. This is where the stator comes in: Made from two non-rotating blade sets and located in a stationary housing between rings of turbine blades, the stator is designed to stop the flying fluid from slowing the engine by hitting the pump.

2. Hydraulic torque converters can actually multiply torque in the right setting

A torque converter is a hydrodynamic fluid coupling that takes the place of a clutch in vehicles with automatic transmissions. In other words, they allow the engine to turn while the machine’s wheels and transmission gears come to a complete stop.

They’re also used to take the rotational power from a prime mover, like an engine or motor, and transfer it to the driven load.

But here’s the kicker ““ hydraulic torque converters can actually end up multiplying torque and functioning as a reduction gear if there is a sufficient difference between the input and output rotational speed.

3. Hydraulic torque converts run better, longer and more efficiently

Hydraulic torque converters are more fuel-efficient and promote longer life in your engine and industrial equipment.

They offer better shock protection and more reliable automatic braking, which makes your heavy machinery operate more smoothly overall.

Hydraulic Torque Converters from K&L Clutch

If you are looking for torque converters for your heavy machinery or need repairs, give us a call or contact us via our online form. We provide you with the highest quality products and services globally, at the very best price.